Add to Cart

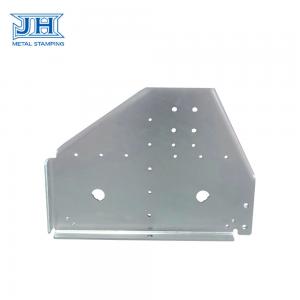

Wall Mount Bracket Heavy Duty Customized Zinc Plating Stamping

Product description

The material used to manufacture our elevator brackets is Cold Rolled steel with zinc plating.

Company common manufacturing process is Blanking-piercing-bending-forming.

The material we used before are Aluminum, copper/brass, Stainless steel, Cold and hot rolled steel,

Hot-dip galvanized steel, and Tin Plate.

Company biggest characteristic is we producing and supplying customized products.

Anyway, we will follow customers' request.

Similar product Images

Product Specification

| Type | Elevator brackets |

| Material | Cold Rolled Steel |

| MOQ | Negotiable |

| Product specifications | Customized for All products / According to Drawings |

| Surface treatment | Zinc Plating |

| Tolerances | 0.05mm |

| Process | Forming Process |

| Sample | Any trial order is welcomed |

| Advantages | 1. We are direct factory, best price will offer. 2. Had 20 years experience for manufacturing, exporting, and quality guaranteed. 3. Factory visit welcome. 4. With independent open mold capacity, all sorts of stamping parts can be manufactured according to customer's requirement, drawing, design or samples (OEM). |

Corporate strength

We pride ourselves on providing outstanding customer service, competitive prices, priority response,

and problem-solving capabilities.Our dedication to continually improving our business and our customer

relationships continues to pay off our customers, employees and the company.

FAQ

Q: What is the payment method?

A: We accept TT (Bank Transfer), L/C.

1. For total amount under US$3000, 100% in advance.

2. For total amount above US$3000, 30% in advance, the rest against the copy document.

Q: What is your MOQ?

A: MOQ depends on our client's needs, besides,we welcome trial order before mass-production.

Q: What is the production cycle?

A: It varies a lot depending on product dimension,technical requirements and quantity. We always try to

meet customers' requirement by adjusting our workshop schedule. Usually our normal lead time is 25-30

days for 1 full container; it is also up to the actual production situation and products structure.

Q: If you make poor quality goods,will you refund our fund?

A: We make products according to drawings or samples strictly until them reach your 100% satisfaction.

And actually we won't take a chance to do poor quality products.We are proud of keeping the spirit of

good quality.

Q: Could you offer competitive tooling cost?

A: We have own mold work-shop in our factory, for competitive tooling cost and on-time

samples.